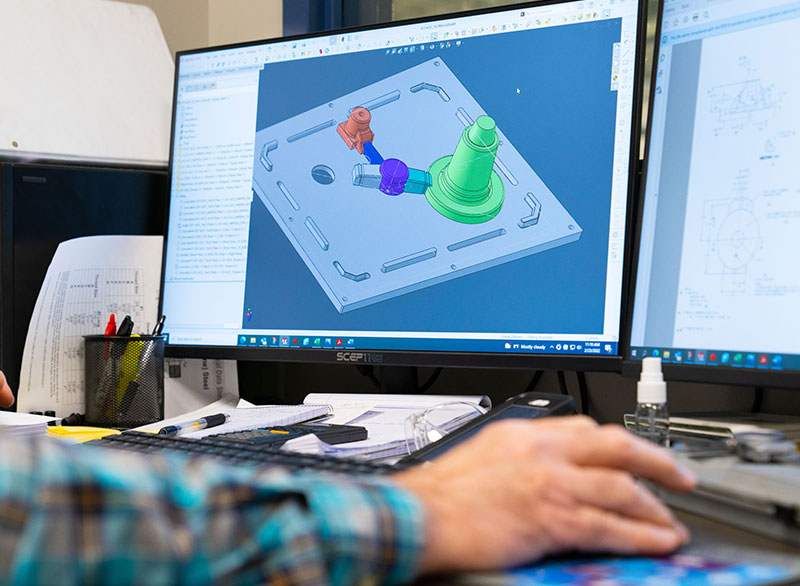

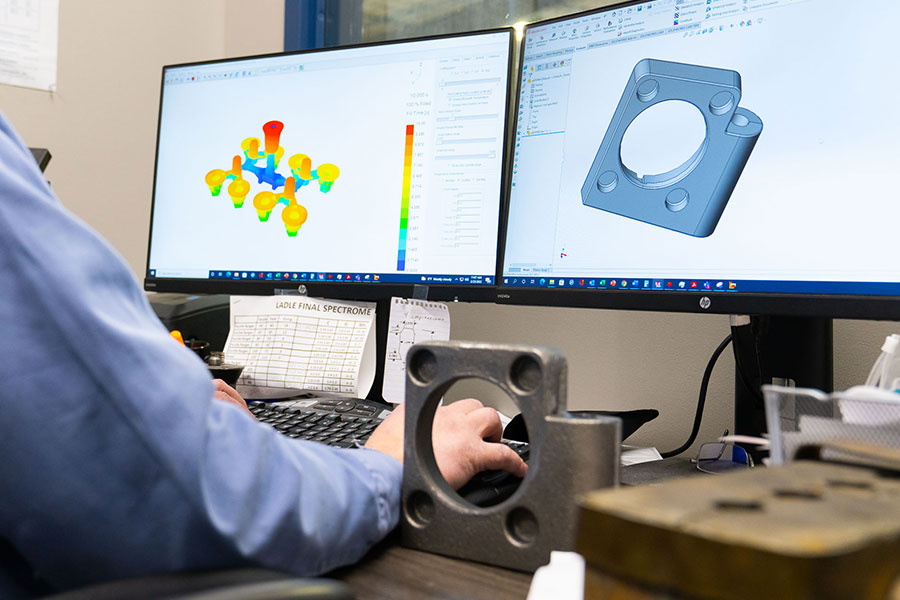

Casting Design

Ferroloy’s technical team works directly with customers to identify castable parts and provide a price quote. It is not uncommon for a customer to capture up to a 60% cost reduction by converting a weldment to a casting. Learn more about our iron casting conversion services and the value of working with Ferroloy.

Machining

We use DMG Mori and Makino CNC 4 and 5 axis milling centers which enable us to machine parts up to 20″ x 20″ x 10″. In addition, we use DMG Mori NLX CNC lathes for turning parts up to 12″ diameters. Our fixtures are designed part specific to ensure print tolerances are strictly adhered to.

To support our capabilities to machine and hold tight tolerances we have several measurement tools at our disposal including CMM, air gauging and profilometers.

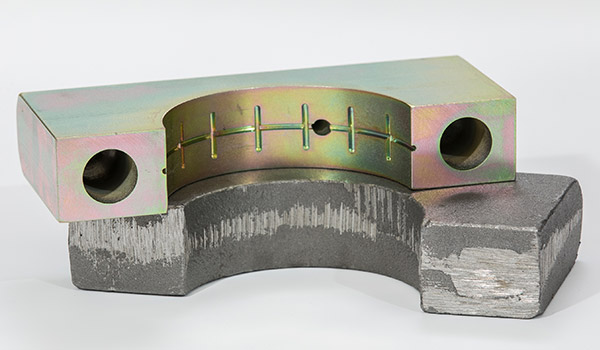

Heat Treating

Many metal castings meet the specified property requirements in their as-cast form, but there are times when the products application requires unique properties to ensure the material functions as needed. In these instances, thermal treatment can change the mechanical properties such as a material’s strength, consistency or ductility. Choosing the treatment that will be most economical calls for an understanding of the various processes and knowledge of material science. We have strategic relationships with local heat treating suppliers that allow us to anneal, normalize, stress relieve, and austemper parts with quick turnaround times. The use of third party suppliers allow us to provide the best capability to meet our customers’ needs.

Coatings

In many cases a casting may require paint, powder coating, zinc coating or other finish for its final application. Ferroloy partners with local suppliers to expedite the process and minimize lead times.

Tool Making & Repair

All patterns and core boxes begin to wear over time and use. Our in house pattern shop has the capability to make or repair all patterns and core boxes. We also have valuable, strategic relationships with pattern shops and can be of great assistance working with the customer and pattern shop to develop tooling that can produce parts more efficiently with fewer defects.

Our internal capabilities include a dedicated 3-axis CNC mill, laser scanning, 3D CAD modeling, solidification modeling and 3D nylon printing.