Molding Production

A mold is produced by using a pattern pressed in green sand to form a cavity of a desired shape such that molten metal can be poured into the cavity. The mold cavity needs to retain its shape until the metal has solidified and the casting is removed.

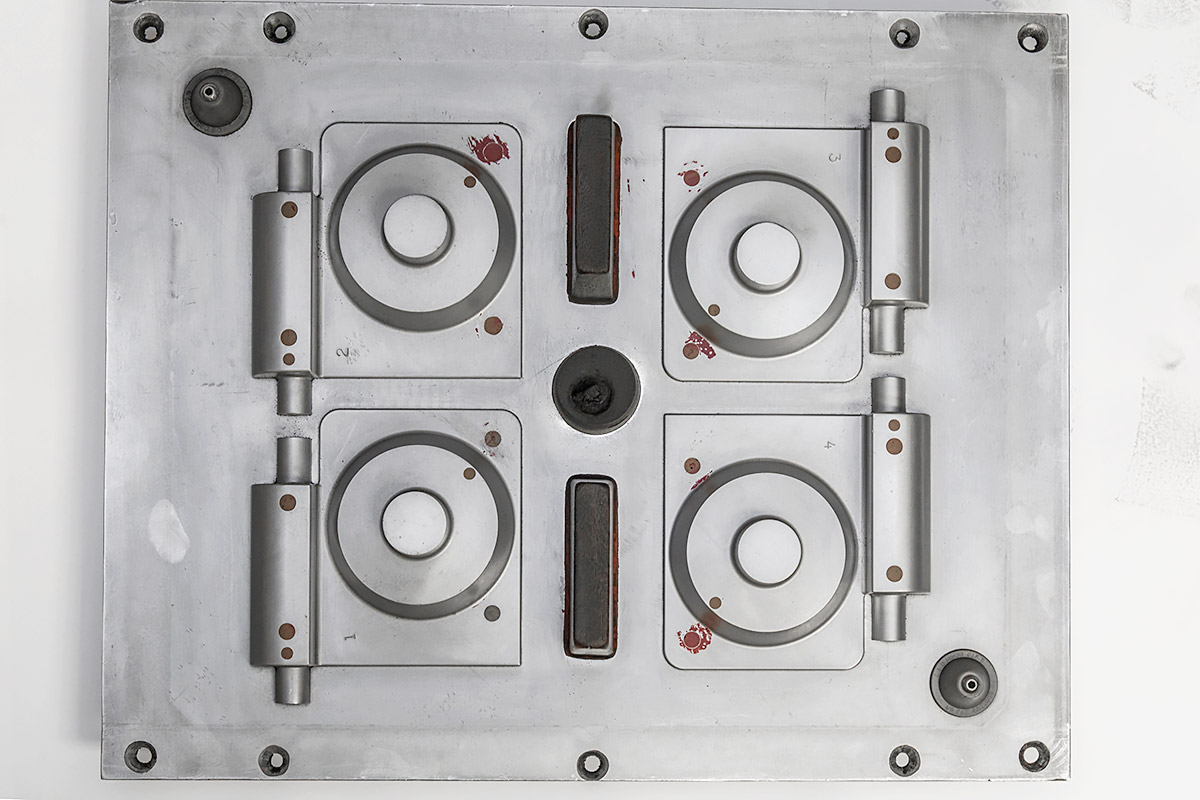

Molding Machines

We use Sinto 16×20 FDNX molding machines. Each machine has the capacity to produce up to 40 molds/hour. We specialize in castings that range in size from .5 to 50 lbs.

Sand Conditioning System

Our foundry runs an automated sand conditioning system consisting of a Simpson sand muller with the capacity to mull 32,000lbs/hr. The quality is continuously monitored automatically by Green Sand Control systems to monitor every batch.

Pattern Management

All customer patterns are logged in the tooling module of Odyssey (ERP). Each pattern is assigned a designated location with production history and repairs tracked.